Design & Application

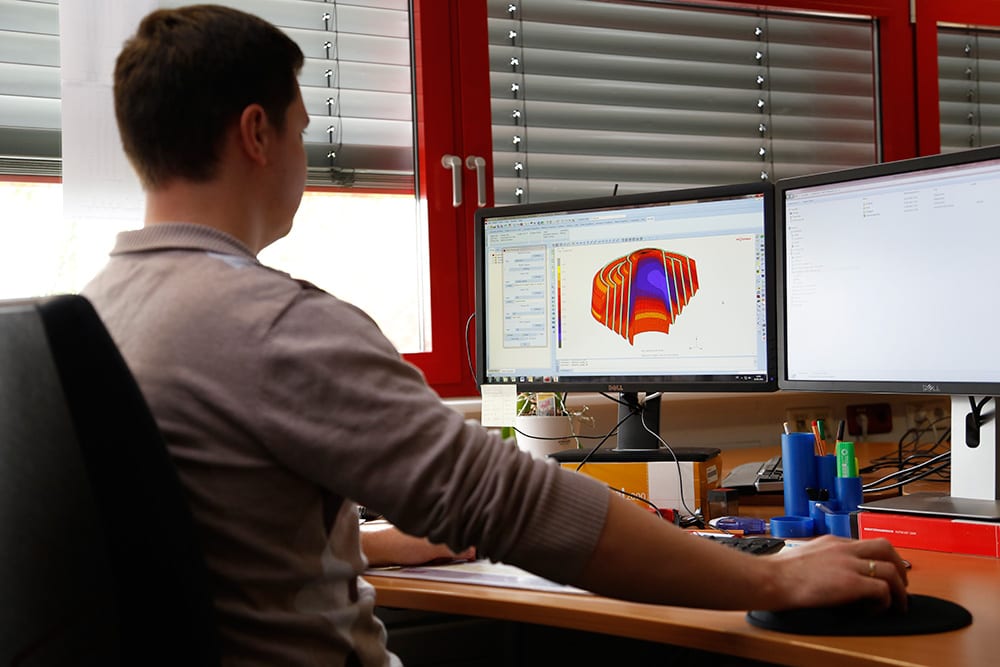

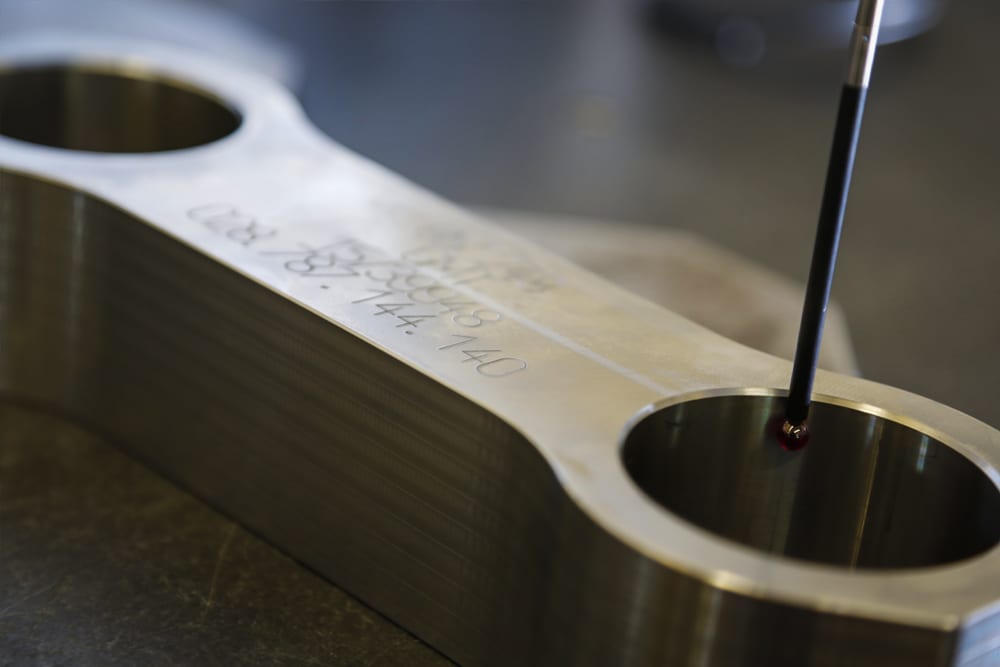

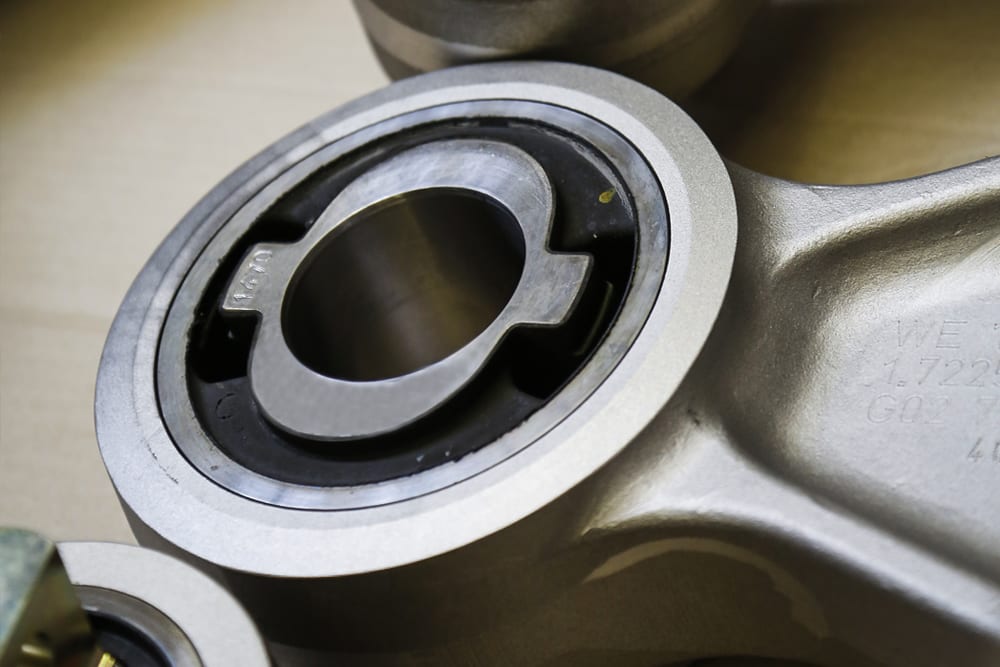

GMT provide full design and application support. Parts can either be selected from thousands of existing products or else a new bespoke solution can be designed to meet unique customer requirements. In-house Finite Element Analysis can be used to ensure designs are ‘right first time’ thereby reducing the time required to bring new products to full production.